Blog Series:

Automated Motorized Total Stations (AMTS): Common Issues and How to Correct Them (Blog 2 of 3)

In our first blog in the “Automated Motorized Total Station (AMTS): Common Issues and How to Correct Them” series, we explored Geometry and how the proper geometry can ensure accurate monitoring. We looked at the proper way to set up your Total Station Land Surveying Equipment network in order to get good, reliable measurements and concluded that Software Cannot Fix Bad Geometry.

In our first blog in the “Automated Motorized Total Station (AMTS): Common Issues and How to Correct Them” series, we explored Geometry and how the proper geometry can ensure accurate monitoring. We looked at the proper way to set up your Total Station Land Surveying Equipment network in order to get good, reliable measurements and concluded that Software Cannot Fix Bad Geometry.

In other words, if you have laid out your Automated Motorized Total Station network poorly or installed your automatic total station surveying equipment in a way that will allow it to read insufficient reference points, there’s no amount of magical software that can fix your data and turn bad data into good data. If you missed it, you can access the blog here.

In this blog, we will explore the second issue: Inappropriate Reference Location.

Reference Prisms – What They Are and Why They’re Important

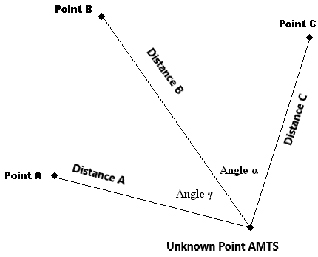

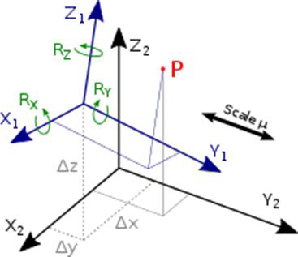

Reference prisms are prisms that we define to be stable locations. An Automated Total Station instrument measures the reference prisms and then records its original location to use as a reference. The remote Total Station equipment is able to calculate where it must be based on where it measures the reference prisms to be at any given time. This is called resectioning (we won’t get in the mathematics here, but it’s all based on geometry, trigonometry and a process called the Helmert Transformation). The AMTS assumes that the prism is still at the original location then calculates where it is relative to that prism. Therefore, reference prisms allow the total station to correct itself for any drift in the instrument. Drift can be caused by the total station surveying instrument itself or normal changes at the location where the AMTS is located (e.g., temperature changes or pressure changes). Because the reference prisms are the basis for all measurements by the total station land surveying equipment, it is vitally important for them to be stable throughout the life of the monitoring program.

Choosing A Stable Structure

First, as noted above, we always want to install reference prisms in locations where they will be stable, making sure that they are well out of the Zone of Influence of whatever event we are trying to monitor.

For example, if we are monitoring an excavation site using the construction total station, we do not want to install reference prisms on a wall directly adjacent to the excavation. The prisms typically need to be at least a hundred feet from the Zone of Influence so that we are not re-sectioning based on the movement caused by the construction.

Second, to ensure physical stability of the prisms, not only do we have to take into consideration the construction or whatever event that we are actually monitoring, we also need to look at the physical properties of what we are installing the prism on.

For example, we don’t want to install the prism on temporary scaffolding or any kind of structure that might be likely to move on its own outside of influence from the construction.

A general rule of thumb is the larger or more massive a structure is, the better it would be for using as a reference location. However, we cannot stop here.

We also have to look at other outside influences on the stability of those prisms. If the surface on which a prism is mounted is susceptible to movement from wind or, perhaps, thermal effects on the surface (e.g. sun exposure on a metal surface), the stability of the prism can be negatively impacted. So, shady spots are generally better than those that have high sun exposure.

For example, if a prism is mounted on a billboard that is on the top of a building, you have to consider the wind blowing on that large surface area of the billboard, which can cause it to move and thus, create instability for the prism. Or, if a prism is on a structure made of black metal, daily sun exposure can affect the position of the prism.

Other Influences on Prism Stability

Once we have chosen a stable structure on which to install our prisms, we then need to consider other external influences that can affect the way the prisms are read. Your prisms need to be protected from potential damage from traffic or anything else that can cause them to be moved or “knocked off” of the structure on which they are mounted.

When a reference prism is removed or added to an automatic total station network it will change the adjustment made to the total station’s position and cause all of the data in that network to shift. So, if one or more of your prisms are damaged or destroyed, you will see jumps in your data because that prism will be removed from the calculations. Naturally, this is something you want to avoid.

Avoiding Obstructions

As we discussed in the first blog in this series, you want to ensure clear sight lines between your automated total stations and your prisms. It is important to make sure that the total station surveying equipment can actually see ALL of your prisms; see them WELL; and see them REPEATEDLY.

If a prism is placed in a location where it might be “blocked” from the sight line of the remote total station instrument, it will have the same effect as a damaged prism or one that has been removed altogether from your network. If a prism is blocked or obstructed, its particular reference point will be removed from the total station’s calculations and thus, will cause jumps in your data.

A Look Ahead to Our Next Blog: Weather and Refraction

Weather and objects in the environment can also have huge impacts on your monitoring programs. When automated motorized total station surveying equipment has to “shoot” its signal through something that changes the refractive coefficient of the air, we get refraction and our measurements are impacted.

We will explore weather and refraction in detail in our next and final installment of this 3-blog series, “Automated Motorized Total Stations (AMTS): Common Issues and How to Correct Them.” Don’t miss it!

Specto Technology offers hands-on, in-person training classes on the use of Automated Motorized Total Stations (AMTS) and other helpful trainings several times a year in our Linden, New Jersey Training Center. We also offer custom training classes. Our AMTS trainings include a troubleshooting section which outlines the common issues that have been experienced with the Automated Total Station and how to correct them. If you have not had the opportunity to attend one of the sessions yet – or if you have attended a training and would like to revisit the information – you can learn some of the basics in our 3-blog series: Automated Motorized Total Stations (AMTS): Common Issues and How to Correct Them. Above is the second of the three blogs.

-

Wildfire Cleanups and Recovery: Perimeter Air Quality Monitoring

Wildfire Cleanups and Recovery: Perimeter Air Quality Monitoring -

Protection from Wildfire Smoke – California, Washington and Oregon

Protection from Wildfire Smoke – California, Washington and Oregon -

What is Respirable Silica Dust and Why Do You Need to Monitor It?

What is Respirable Silica Dust and Why Do You Need to Monitor It? -

New Jersey Perimeter Air Quality Monitoring (PAM) Technical Guidance Explainer

New Jersey Perimeter Air Quality Monitoring (PAM) Technical Guidance Explainer -

Air Quality Matters: Wildfires & AQI

Air Quality Matters: Wildfires & AQI -

Aeroqual Ranger™ Cloud from Specto Technology - Configure Alerts

Aeroqual Ranger™ Cloud from Specto Technology - Configure Alerts -

Aeroqual Ranger™ Cloud from Specto Technology - Connect to Wi-Fi

Aeroqual Ranger™ Cloud from Specto Technology - Connect to Wi-Fi -

Aeroqual Ranger™ Cloud from Specto Technology - Swapping Sensor Heads

Aeroqual Ranger™ Cloud from Specto Technology - Swapping Sensor Heads -

Aeroqual Ranger™ Cloud from Specto Technology AQI

Aeroqual Ranger™ Cloud from Specto Technology AQI -

Assembly of a pole mounted solar panel system (3 panels)

Assembly of a pole mounted solar panel system (3 panels)