This 6-part blog series explores the use of MEMS Accelerometers for vibration monitoring in construction and blasting applications, and the five most prevalent issues with these devices, as outlined in Instantel’s recent white paper, “Limitations of MEMS Accelerometers for Vibration Monitoring Systems.”

Instantel’s paper concluded that, when it comes to vibration monitoring for construction and blasting applications, data from MEMS Accelerometers can be unreliable when measuring high frequency vibrations caused by explosives, heavy construction equipment, jackhammers, pile drivers and similar activities. The paper outlined five major concerns, including:

- Vibration Rectification Error (VRE)

- Operational limits at high frequencies

- Aliasing

- Noise and the noise floor

- Regulatory compliance

Concern #2: Operational Limitations at High Frequencies

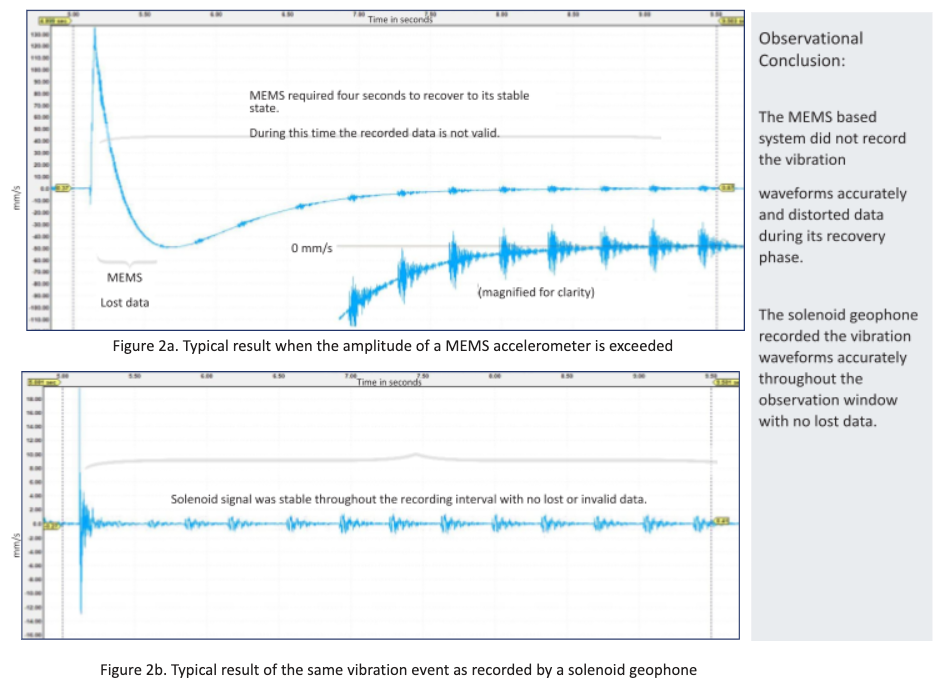

MEMS accelerometers fall prey to two limitations when it comes to the method by which they process incoming data: the inability to filter frequencies higher than 500 Hz and a limited detection range.

MEMS accelerometers use velocity amplitude to measure vibrations, converting acceleration measurements to velocity for data output. In doing so, the MEMS units convert all data received without exception. This causes a problem in that higher frequency vibrations, particularly those over 500 Hz, are outside the limits of most vibration standards and are, therefore, typically ignored when studying vibration effects. Since MEMS accelerometers do not filter out these high frequency vibrations, they can often produce unreliable data.

In addition, hoe ramming, blasting and similar activities typically produce higher frequency vibrations which are outside of the range within which MEMS devices can detect vibrations, further distorting the data produced.

Bottom Line

When high frequencies are present – as they most certainly will be when measuring vibrations from construction activity – the method by which MEMS accelerometers measure vibration frequencies and the operating limits of the devices altar the data, thus rendering it unreliable. These errors are not preventable.

Read Instantel’s findings here. “Limitations of MEMS Accelerometers for Vibration Monitoring Systems.”

Part 4 of this 6-part blog series will focus on aliasing.

-

Wildfire Cleanups and Recovery: Perimeter Air Quality Monitoring

Wildfire Cleanups and Recovery: Perimeter Air Quality Monitoring -

Protection from Wildfire Smoke – California, Washington and Oregon

Protection from Wildfire Smoke – California, Washington and Oregon -

What is Respirable Silica Dust and Why Do You Need to Monitor It?

What is Respirable Silica Dust and Why Do You Need to Monitor It? -

New Jersey Perimeter Air Quality Monitoring (PAM) Technical Guidance Explainer

New Jersey Perimeter Air Quality Monitoring (PAM) Technical Guidance Explainer -

Air Quality Matters: Wildfires & AQI

Air Quality Matters: Wildfires & AQI -

Aeroqual Ranger™ Cloud from Specto Technology - Configure Alerts

Aeroqual Ranger™ Cloud from Specto Technology - Configure Alerts -

Aeroqual Ranger™ Cloud from Specto Technology - Connect to Wi-Fi

Aeroqual Ranger™ Cloud from Specto Technology - Connect to Wi-Fi -

Aeroqual Ranger™ Cloud from Specto Technology - Swapping Sensor Heads

Aeroqual Ranger™ Cloud from Specto Technology - Swapping Sensor Heads -

Aeroqual Ranger™ Cloud from Specto Technology AQI

Aeroqual Ranger™ Cloud from Specto Technology AQI -

Assembly of a pole mounted solar panel system (3 panels)

Assembly of a pole mounted solar panel system (3 panels)