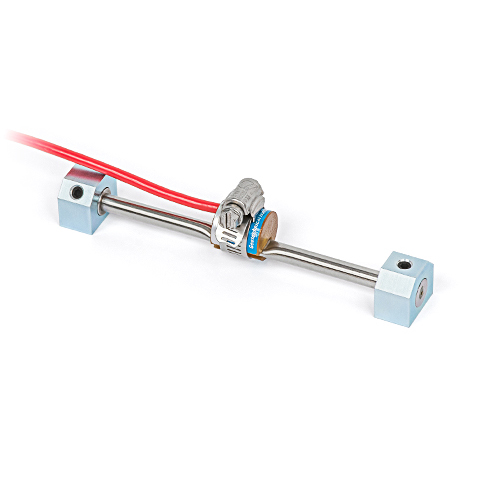

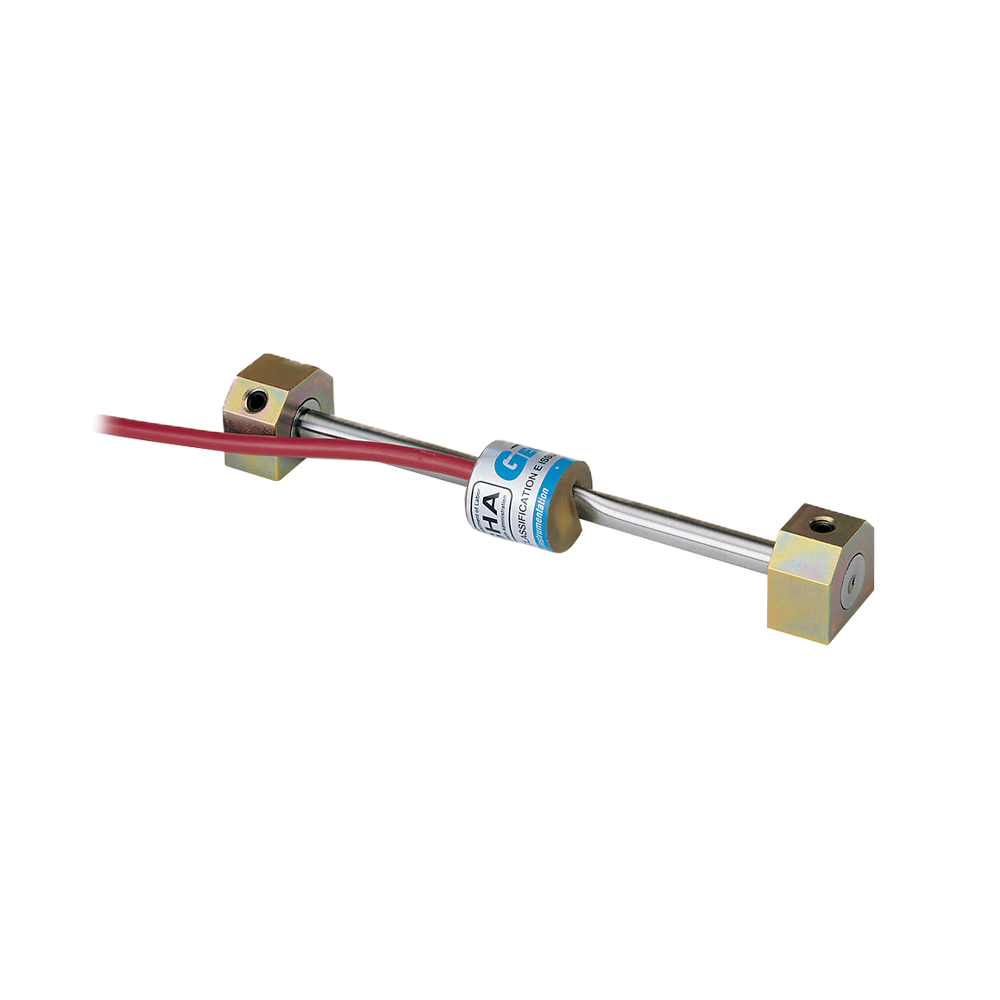

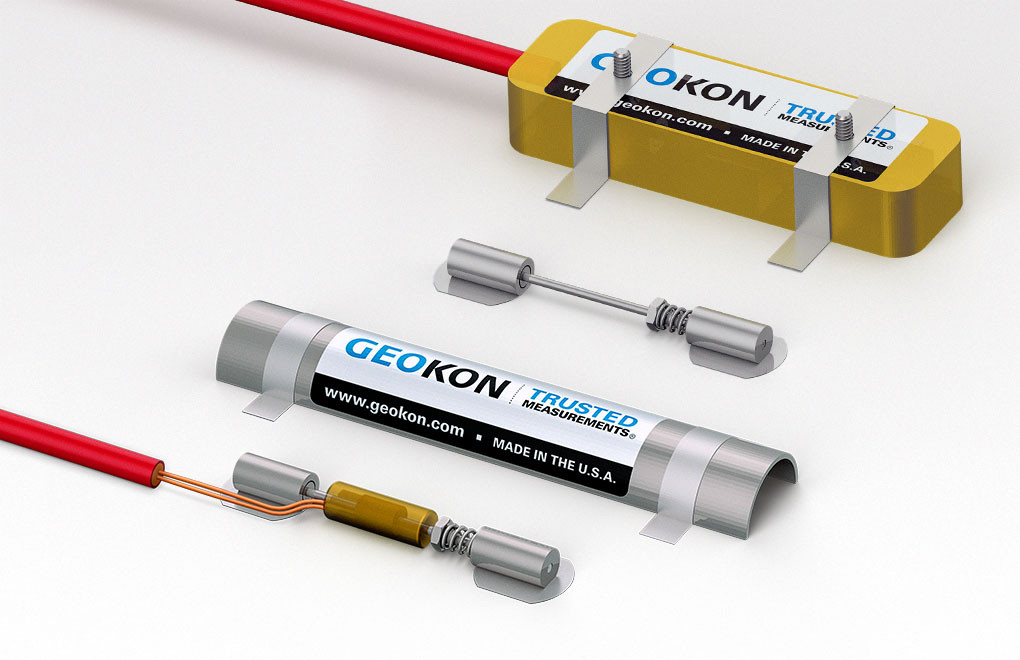

Vibrating Wire Surface Mount Strain Gauge

Product Information

The Model 4000 Strain Gauge is designed primarily for arc welding to steel structures such as tunnel linings, excavation bracing, piles and bridges. The gauge has a 150 mm gauge length (longer or shorter versions are also available), a 3000 µε range and a 1 µε sensitivity. The gauge can be adapted for bonding to concrete or for bolting to steel surfaces by modification of the end blocks.

Spot weldable gauge is also available https://www.geokon.com/4100-4150.

Product Features

- Due to the sensor’s long life and high reliability, vibrating wire strain gauges are the most robust solution to monitor strain in concrete and metal structures

- There are five different types of strain gauge, each for differing situations of strain gauge testing (See additional information at the bottom of this page)

- Standard Range¹3000 µε

- Resolution1.0 µε

- Accuracy²±0.5% F.S.

- Nonlinearity<0.5% F.S.

- Temperature Range³−20°C to +80°C

- Active Gauge Length³150 mm

Product Benefits

- VW sensors allow long cable runs

- Sensors have proven long term stability

- Suitable for manual or remote reading

- Robust and reliable

- Long-term stability

- High resistance to water intrusion and lightning damage

- Ability to be used with long signal cables

Typical Applications Include

- Vibrating wire strain gauge instrumentation is used to monitor strain in steel or in reinforced concrete

- Tunnel linings

- Excavation bracing

- Arches

- Struts

- Sheet piling

- Piles

- Bridges